Today’s nuclear power reactors shut down every 18 to 24 months to refuel. During a refueling outage, a third or more of the fuel assemblies are removed from the reactor core and placed in metal storage racks inside spent fuel pools. New fuel assemblies are loaded into the reactor core and the unit restarted for another operating cycle.

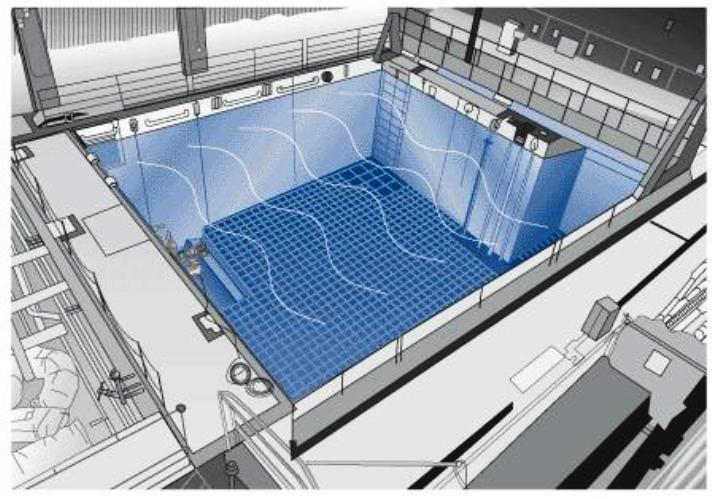

Spent fuel pools have thick concrete walls and floors and contain approximately 400,000 gallons of water. A system continuously draws water from the spent fuel pool, cools it, and returns it to the pool. Otherwise, the decay heat being emitted from radioactive byproducts in the spent fuel assemblies would boil away the water. Water is needed to protect the spent fuel assemblies from damage caused by overheating. Water also functions as a shield protecting workers from exposure to lethal amounts of radiation.

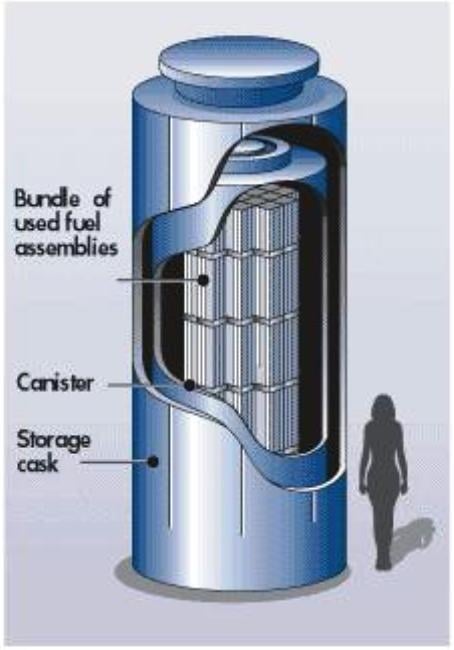

As the storage racks in spent fuel pools approach being completely filled, owners turn to dry storage. After spent fuel assemblies have been in spent fuel pools for at least five years, they may be transferred into dry storage, such as the cask shown in the picture. The spent fuel assemblies continue to emit decay heat. But those emissions have declined to the level where convective cooling—the natural flow of air due to the chimney effect—is enough to protect them from overheating damage.

For many years, UCS has advocated that rather than waiting until spent fuel pools are nearly filled, it would be safer and more secure to accelerate the transfer of spent fuel assemblies into dry storage.

Even the nuclear industry concedes that dry storage poses less risk than spent fuel pool storage, as this story shows.

Yankee Rowe and Liability Insurance

The Yankee Rowe nuclear plant permanently shut down in October 1991. Twelve years later, its owner asked the NRC for permission to reduce its liability insurance limits.

As the March 2011 disaster at Fukushima in Japan demonstrated, an accident at a nuclear power plant can cause immense offsite consequences. The potential liability is so large that nuclear plant owners cannot afford the annual liability insurance premiums. So, the Price-Anderson Act was signed into law in 1957 to provide federal liability insurance protection. Individual plant owners are required to obtain private liability insurance up to a certain level with Price-Anderson covering damages exceeding that amount.

When Yankee Rowe was operating, its owner was required to obtain $200 million of liability protection against offsite damages from a nuclear accident. When reactor operation permanently stopped, its owner requested and the NRC approved a reduction in the mandated liability protection amount to $100 million.

After all spent fuel assemblies had been transferred from the spent fuel pool into dry storage, the owner asked the NRC to approve a further reduction in its liability protection level from $100 million to $25 million. The owner justified this reduction on grounds that dry storage “eliminates the available radiological source term remaining on the site for reasonably conceivable radiological accident scenarios that could have significant offsite consequences.” In other words, the risk to people living around the plant from the spent fuel assemblies when stored in spent fuel pools is eliminated once they have been moved into dry storage.

Our Takeaway

It’s said there’s no such thing as a free lunch. If so, this adage also applies to irradiated fuel. Irradiated fuel is not inherently safe when it’s in the reactor core, the spent fuel pool, or in a dry cask.

There is such a thing as a cheaper lunch. This concept also applies to irradiated fuel. Irradiated fuel poses less risk when in a spent fuel pool than when in a reactor core and poses even less risk when in dry storage than when in spent fuel pools. The liability insurance protection levels sought by Yankee Rowe’s owner reinforce this reality. When money talks, we should listen.

Fukushima graphically demonstrated this reality. The irradiated fuel in the reactor cores of Units 1, 2, and 3 posed the greatest risk. Despite heroic efforts by gallant workers, this fuel overheated and caused tens of thousands of people to be evacuated and sheltered.

The irradiated fuel in the spent fuel pools of Units 1, 2, 3, and 4 posed the next largest risk. But for reactor buildings being blown open due to hydrogen detonations, helicopters and fire trucks may not have been able to provide the tons of makeup water needed to prevent boiling spent fuel pools from adding to Fukushima’s tragedy.

The 408 irradiated fuel assemblies in dry storage at Fukushima posed the least risk. The tsunami waters temporarily submerged the dry casks. During that period, water did what air could not do – reduce decay heat. Once the flood waters receded, the chimney effect automatically resumed cooling the irradiated fuel. When disaster teaches hard lessons, we should learn.

Dry storage is the safer and more secure way to manage the risks from onsite spent fuel storage. Shame on the federal government and the nuclear industry if simple steps are not soon taken to better protect millions of Americans by thinning out overcrowded spent fuel pools.

“Fission Stories” is a weekly feature by Dave Lochbaum. For more information on nuclear power safety, see the nuclear safety section of UCS’s website and our interactive map, the Nuclear Power Information Tracker.