Nuclear Energy Activist Toolkit #59

Medical professionals diagnose the health of their patients using non-destructive techniques (keeping with the Hippocratic Oath to do no harm) like taking temperatures and pulses and, when necessary, peering inside bodies using X-rays and Cat-scans.

Medical coroners, on the other hand, can use destructive techniques on persons when determining the causes of their deaths. Chest cavities and skulls are cut open to enable organs to be assessed. Tissue samples may be cut from bodies for microscopic examinations.

Insights gained during autopsies supplement the information gathered from treatments and examinations of living patients to broaden the knowledge of human health, allowing medical professionals and researchers to make health care advances.

Nuclear autopsies have been undertaken, and more are planned, for similar purposes—to supplement information gathered during tests and inspections conducted during reactor operation and support technological advances.

For example, the NRC outlined “harvesting” (their use, my re-use) several components during the decommissioning of permanently shut down nuclear power reactors.

Samples from the Zorita nuclear plant

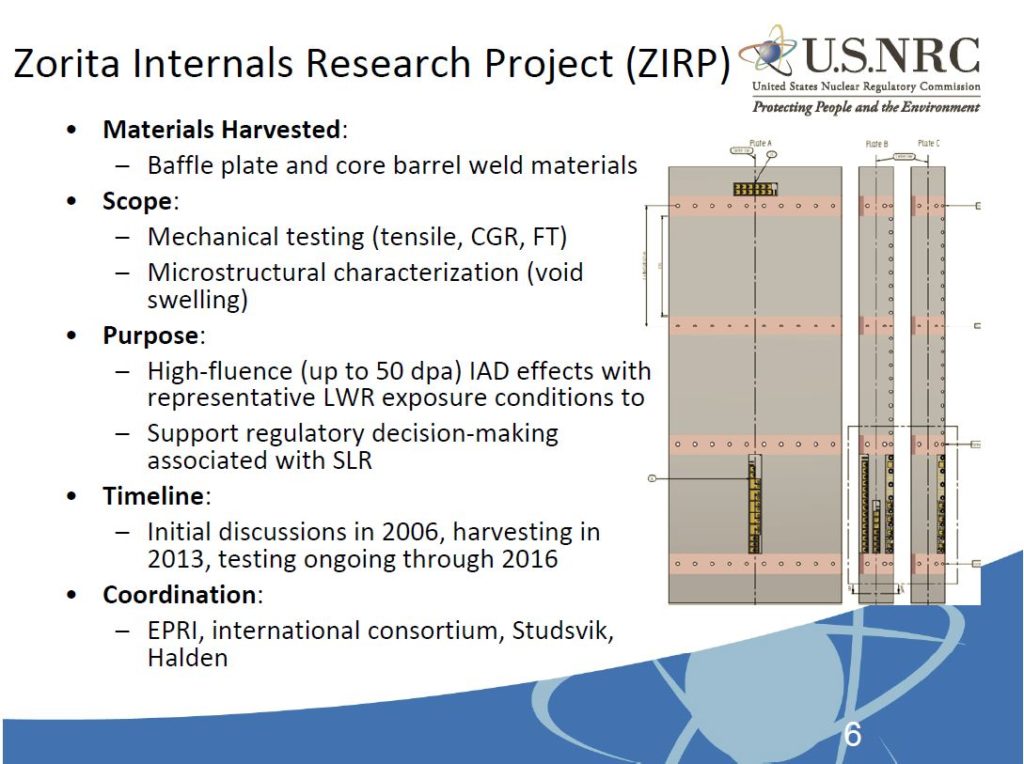

Samples from the baffle plate and core barrel were harvested from the José Cabrera Nuclear Power Station (also known as the Zorita nuclear plant) in Spain as part of the Zorita Internals Research Project.

Fig. 1. (click to enlarge) (Source: Nuclear Regulatory Commission)

Zorita was a pressurized water reactor similar to about two-thirds of the reactors currently operating in the United States. The baffle plate and core barrel formed a metal enclosure around the nuclear fuel within the reactor pressure vessel. They function to direct cooling water flow through the reactor core. Metal specimens attached to the core barrel and other internal components are periodically removed during refueling outages over the reactor’s lifetime for laboratory analysis of radiation effects.

The Zorita samples supplement those insights. Among other things, the results from the examinations will factor into the NRC’s decision-making about subsequent license renewal (SLR)—operating reactors beyond 60 years.

Additionally, there are plans to for samples from concrete structures surrounding the reactor pressure vessel at Zorita to be harvested. Previous concrete samples have been harvested from the containment building at Crystal River 3, from the shield building at Davis-Besse, and from the auxiliary building at Seabrook. The samples at Zorita will come from concrete structures within the containment building and closer to the high temperature and high radiation emitted from the reactor pressure vessel.

Fig.. 2. (click to enlarge) (Source: Nuclear Regulatory Commission)

Samples from the Zion nuclear plant

There are plans to harvest neutron absorber materials from the spent fuel pool at the Zion nuclear plant in Illinois, which permanently shut down a decade ago.

Fig. 3. (click to enlarge) (Source: Nuclear Regulatory Commission)

Spent fuel pools originally relied on geometry to prevent a nuclear chain reaction—the fuel assemblies in the storage racks were far enough apart to preclude a critical mass from being formed. When reprocessing was eliminated and the repository delayed, spent fuel pools were re-racked to store more fuel assemblies. The fuel assemblies within storage racks are typically closer together than when they are in the reactor core.

To guard against nuclear chain reactions, the walls of the storage racks contain neutron absorbing material. The objective of this material is to “soak” up neutrons emitted by the decay of unstable radioactive byproducts in the nuclear fuel and thus prevent them from interacting with uranium and plutonium atoms to cause fissions. But experience with neutron absorbing materials has not been stellar. There were fabrication problems, degradation problems, leaching problems, analytical problems, and expansion problems to list some of the many problems.

The Zion harvests may complement the humongous trial and error database.

Electrical cables will be harvested from both the Zion nuclear plant in Illinois and Crystal River 3 in Florida. Cables consist of metal wires that carry electricity throughout the nuclear plant wrapped in insulating material that guards against the electricity touching things along the way. The focus is on the cable insulation because it tends to age (degrade) faster at higher temperatures.

Fig. 4. (click to enlarge) (Source: Nuclear Regulatory Commission)

Bottom Line

Harvesting of materials to enable fuller insights from their destructive examinations (i.e., nuclear autopsies) has not waited until nuclear power reactors have permanently shut down. As parts have worn out and been replaced (e.g., steam generators, reactor vessel heads, eroded pipes, etc.), specimens have been harvested and analyzed.

The nuclear industry and the NRC seek to expand those insights by harvesting materials from previously un-examined plant areas. These collections permit real data to replace positions established by extrapolating from other real data and/or by computer analyses. Hopefully, the real data reinforces previous positions. Either way, the real data supports better decision-making in the future.

Nuclear autopsies yield insights that cannot be obtained by other means.

The UCS Nuclear Energy Activist Toolkit (NEAT) is a series of post intended to help citizens understand nuclear technology and the Nuclear Regulatory Commission’s processes for overseeing nuclear plant safety.