Fission Stories #197

The April 8, 2000, Saturday Night Live broadcast featured a skit with cast members pretending to be the rock group Blue Oyster Cult in the recording studio with a famous music producer, played by actor Christopher Walken. The skit is remembered for Walken’s character stating “I gotta have more cowbell.”

The NRC’s Reactor Oversight Process (ROP) needs more cowbell, too.

The Fort Calhoun nuclear plant shut down in April 2011 for a refueling outage. The outage was planned to last a handful of weeks while workers replaced spent fuel assemblies with new assemblies and performed routine maintenance and testing activities. The plan went awry when the ROP identified safety problems that needed to be corrected before the reactor could be restarted.

The operators restarted Fort Calhoun in December 2013 after a short refueling outage morphed into a 32-month safety restoration outage. On March 30, 2015, the NRC announced that it was returning Fort Calhoun to normal handling under the ROP. The NRC also reported expending over 60,000 hours since December 2011 on inspection, assessment and licensing tasks at Fort Calhoun.

60,000 hours is a number without context. To help put this value in context, the NRC reported having expended 6,652 hours, 6,612 hours, and 6,782 hours of total oversight effort at the average nuclear plant in 2011, 2012, and 2013, respectively. So the average nuclear plant received an average of 6,682 hours of oversight from the NRC annually.

Between 2012 and 2014, Fort Calhoun received an average of 18,462 hours of oversight effort each year from the NRC.

Thus, Fort Calhoun received the equivalent of 2.76 nuclear plants’ worth of regulatory oversight attention from the NRC between 2012 and 2014.

Too Little Much, Too Late

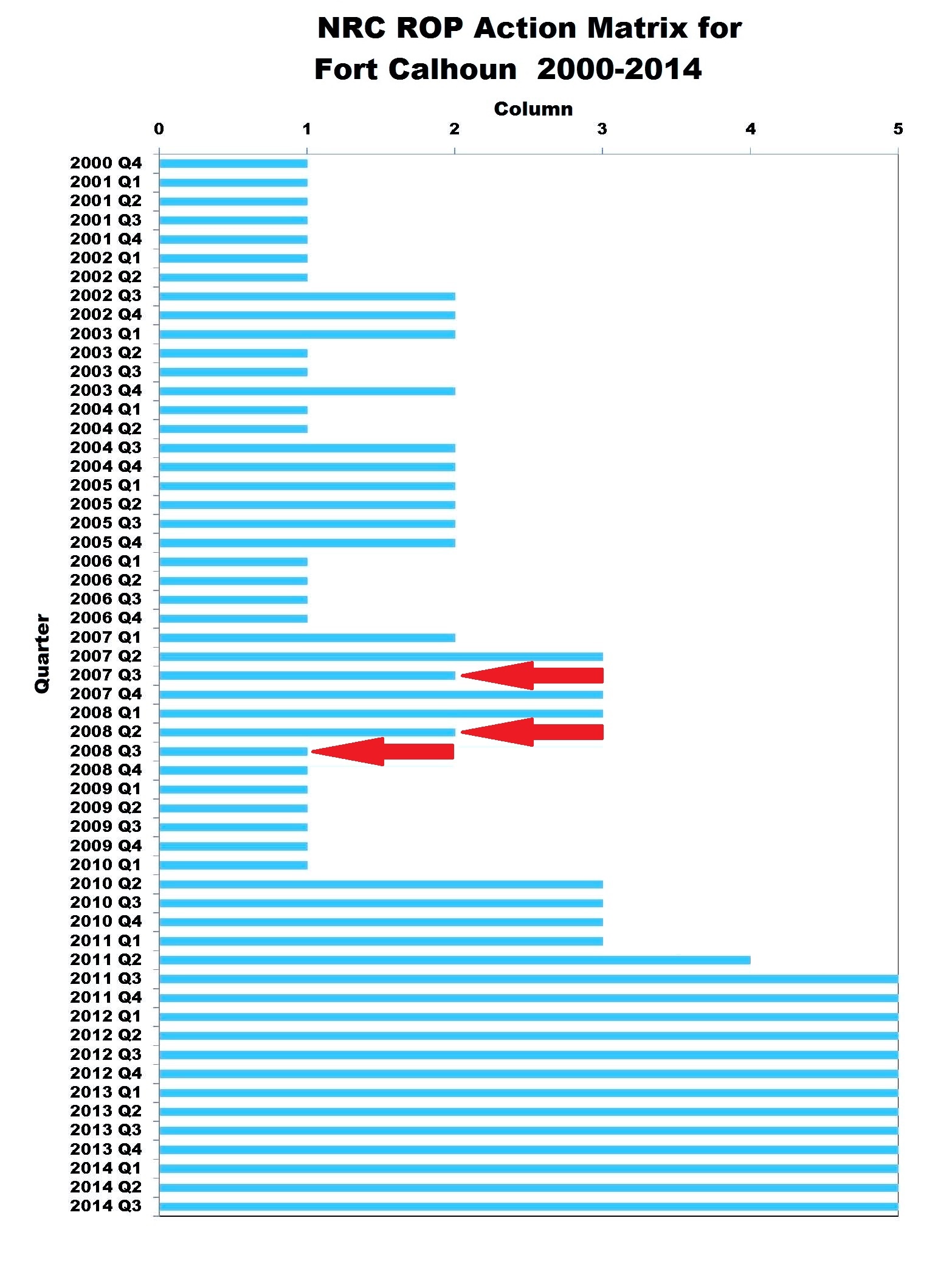

Figure 1 shows where the NRC placed Fort Calhoun within the ROP’s Action Matrix each quarter from the inception in the fourth quarter of 2000 until late 2014.

When performance fell within expected ranges, Fort Calhoun went into Column 1. When performance levels dropped, Fort Calhoun moved into Column 2, Column 3, Column 4, and Column 5 (Column 5 marking when the NRC placed Fort Calhoun under its Manual Chapter 0350 process for especially troubled reactors.)

On two occasions (3rd quarter 2007 and 2nd quarter 2008), the NRC returned Fort Calhoun to Column 2 from Column 3 after determining that safety performance had improved sufficiently. In the 3rd quarter 2008, the NRC returned Fort Calhoun to Column 1 and routine oversight activities.

What’s wrong with this picture?

As UCS documented in No More Fukushimas; No More Fort Calhouns fact sheet, many of the safety problems had existed at the Fort Calhoun plant since 1996. Several dated back to the original construction of the plant in the late1960s and early 1970s. In other words, both the NRC’s baseline inspections (those applied to Fort Calhoun when it resided in Column 1) and its supplemental inspections (those applied when the plant was in Columns 2 and 3) failed to detect ALL of these safety problems.

The problems that kept Fort Calhoun shut down for 32 months were not introduced in 2009 and 2010 after the NRC returned Fort Calhoun to Column 1—they existed all along. Yet the NRC’s ROP missed them all. The ROP missed every single one of them, until after the first quarter of 2011. After that time, finding safety problems was like shooting fish in a barrel—NRC inspectors could hardly turn around without finding yet another safety problem that had to be fixed prior to restart.

So how could more cowbell improve nuclear plant safety?

Rather than expending so much time and effort ensuring that the barn door has been closed, safety would be better served by noticing that it’s open sooner. Cowbells should have sounded long before the first quarter of 2011.

UCS’s fact sheet documented many safety problems that existed at Fort Calhoun for years before the ROP’s inception in 2000. Two of the safety problems involved the emergency diesel generators (EDGs).

EDGs are among the most safety significant components at the plant. Consequently, they receive considerable oversight attention by the NRC. Yet that attention failed to identify either of these two problems that had existed since at least 1990.

And it was not just one miss or even two misses by one NRC inspector—it was a lot of misses by a lot of NRC inspectors over a lot of years. A search of ADAMS, the NRC’s online digital library, identified 39 inspections conducted at Fort Calhoun by the NRC between 2000 and 2010 inclusive that included some oversight of the EDGs.

Something is fundamentally wrong with safety inspections of highly safety significant components that fail to notice safety problems. Finding safety problems isn’t one of the reasons for conducting the safety inspections—it’s the only reason for doing them.

And yet many safety problems remained undetected until 2011 when it took an army of workers more than two years to correct them all.

Our Takeaway

Fort Calhoun is not an isolated case. It marked the 52nd time that a U.S. reactor had to remain shut down longer than a year while safety problems were corrected. The majority of these year-plus outages involved a myriad of safety problems that had existed for months and sometimes years before being noticed.

Consider how safe Fort Calhoun really was on April 10, 2011, or during the preceding years when it operated despite a large and growing number of undetected, uncorrected safety problems. The NRC placed Fort Calhoun in Columns 1, 2, and 3 of the ROP’s Action Matrix. In reality, the presence of the same safety problems that put Fort Calhoun into Column 5 in the third quarter of 2011 should have had it there in the fourth quarter of 2000. The safety problems were there in 2000—it took the NRC another decade to notice them.

Safety and economics both scream out for the NRC to prevent the 53rd time. As more and more pre-existing safety problems accumulate at an operating reactor, the path shortens for an initiating event to lead to nuclear disaster. Put another way, defense-in-depth works better when there are fewer and smaller holes in each protective barrier.

Likewise, finding and fixing problems sooner results in better financial performance. UCS estimated the cost of the 51 year-plus reactor outages before Fort Calhoun to be over $80 billion.

The NRC should construct timelines for each major safety problem corrected during the 2011-2013 outage at Fort Calhoun. The timelines should indicate when the safety problems were introduced and the subsequent NRC inspections that examined the associated system or component. Because the safety problems existed for long durations, many NRC inspection procedures will correlate to each safety problem. The NRC should then evaluate changes to the inspection procedures that increase the likelihood of detecting similar problems in the future. The NRC does not inspect everything; instead, the NRC audits samples. Conducting a Fort Calhoun retrospective would allow the NRC to adjust the number of items selected for each sample or revise the choice of items within the samples or change how it evaluates sample items so as to become more capable at finding safety problems.

The safety problems at Fort Calhoun were not invisible—they were easily found after the 1st quarter of 2011. The NRC must figure out how to make them visible sooner. The NRC must detect safety problems sooner and ring cowbells as the barn doors are opening.

More cowbell = better nuclear safety.

“Fission Stories” is a weekly feature by Dave Lochbaum. For more information on nuclear power safety, see the nuclear safety section of UCS’s website and our interactive map, the Nuclear Power Information Tracker.