The Wolf Creek Generating Station near Burlington, Kansas has one Westinghouse four-loop pressurized water reactor that began operating in 1985. In the early morning hours of Friday, September 2, 2016, the reactor was operating at full power. A test completed at 4:08 am indicated that leakage into the containment from unidentified sources was 1.358 gallons per minute (gpm). The maximum regulatory limit for was such leakage was 1.0 gpm. If the test results were valid, the reactor had to be shut down within hours. Workers began running the test again to either confirm the excessive leak or determine whether it may have been a bad test. The computer collects data over a two-hour period and averages it to avoid false indications caused by momentary instrumentation spikes and other glitches. (It is standard industry practice to question test results suggesting problems but accept without question “good” test results.)

The retest results came in at 6:52 am and showed the unidentified leakage rate to be 0.521 gpm, within the legal limit. Nevertheless, management took the conservative step of entering the response procedure for excessive leakage. At 10 am, the operators began shutting down the reactor. They completed the shutdown by tripping the reactor from 30 percent power at 11:58 am.

Wolf Creek has three limits on reactor cooling water leakage. There’s a limit of 10 gpm from known sources, such as a tank that collects water seeping through valve gaskets. The source of such leakage is known and being monitored for protection against further degradation. There’s a stricter limit of 1 gpm from unknown sources. While such leakage is usually found to be from fairly benign sources, not knowing it to be so imposes a tighter limitation. Finally, there’s the strictest limit of zero leakage, not even an occasional drop or two, from the reactor coolant pressure boundary (i.e., leaks through a cracked pipe or reactor vessel weld. Reactor coolant pressure boundary leaks can propagate very quickly into very undesirable dimensions; hence, there’s no tolerance for them. Figure shows that the unknown leakage rate at Wolf Creek held steady around one-tenth (0.10) gallon per minute during July and August 2016 but significantly increase in early September.

Fig. 1 (Source: Freedom of Information Act response to Greenpeace)

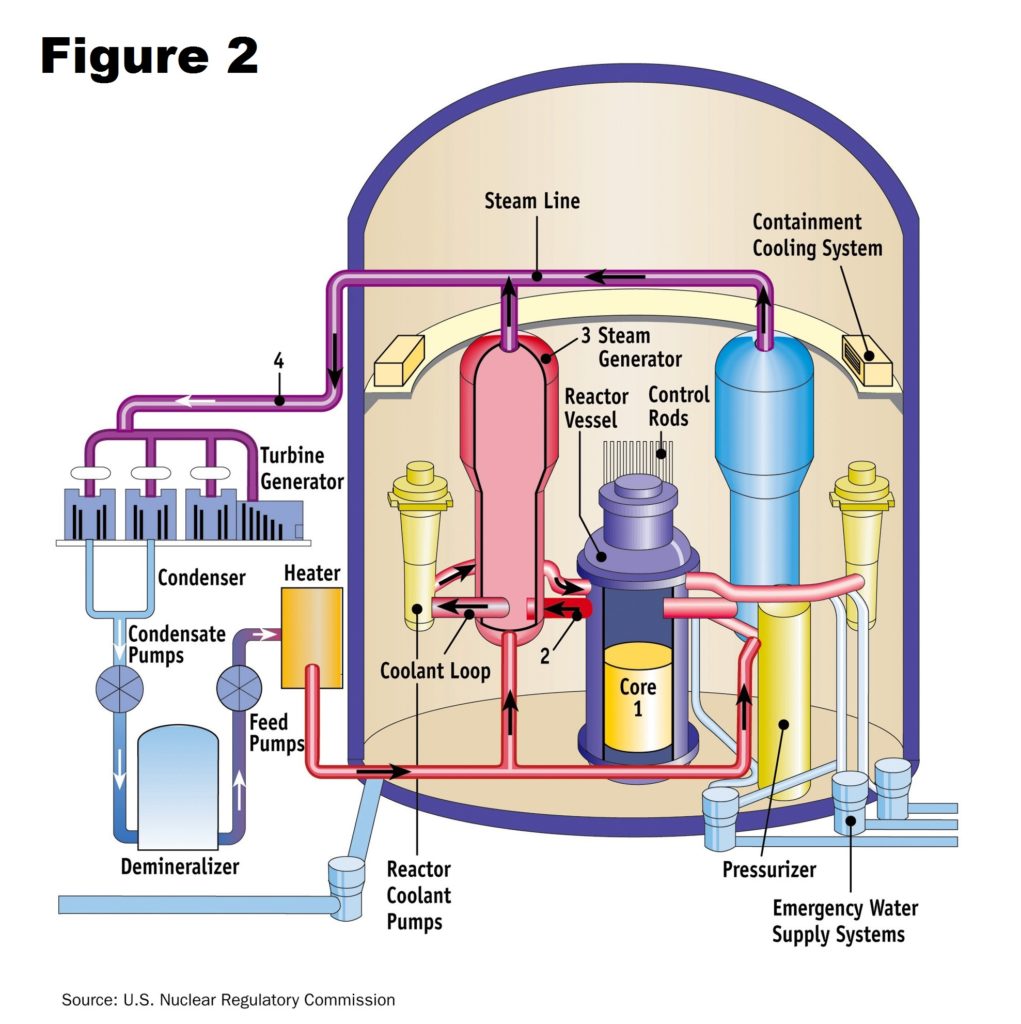

The reactor core at Wolf Creek sits inside the reactor vessel made of metal six or more inches thick (see Figure 2). The reactor vessel sits inside the steel-reinforced concrete containment structure several feet thick. The dome-shaped top, or head, of the reactor vessel is bolted to its lower portion. Dozens of penetrations through the head permit connections between the control rods within the reactor core and their motors housed within a platform mounted on the head. Other penetrations allow temperature instruments inside the reactor vessel to send readings to gauges and computers outside it.

Fig. 2 (Source: Nuclear Regulatory Commission)

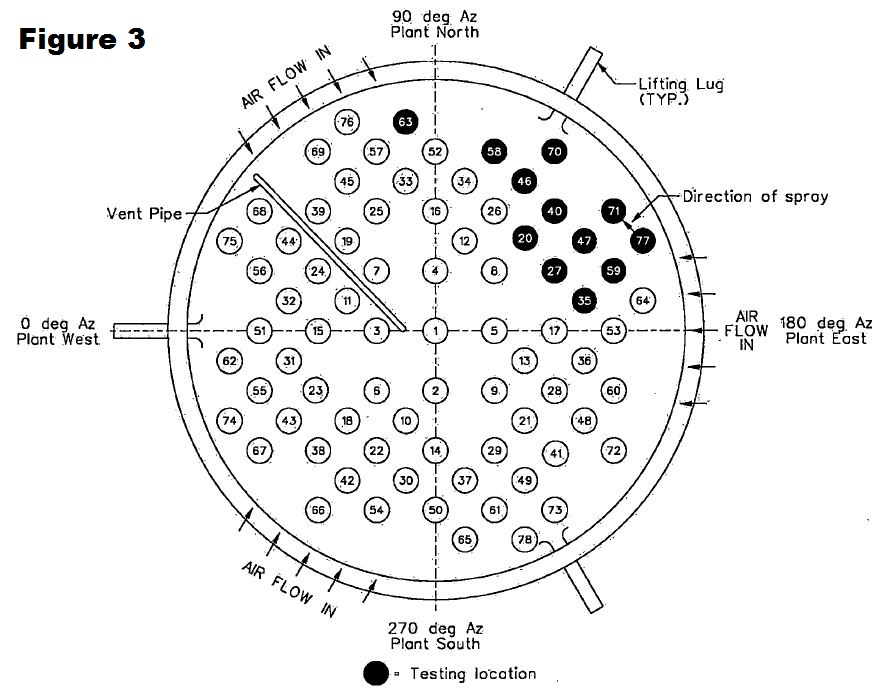

Wolf Creek has 78 penetrations through its reactor vessel head, including a small handful of spares. Workers entered containment after the reactor shut down looking for the source(s) of the leakage. They found cooling water spraying from penetration 77 atop the reactor vessel head. The leak sprayed water towards several other penetrations as shown in Figure 3. Penetration 77 allowed a thermocouple within the vessel to send its measurements to instrumentation.

Fig. 3 (Source: Wolf Creek Nuclear Operating Corporation)

The spray slowed and then stopped as the operators cooled the reactor water temperature below the boiling point. Workers performed a closer examination of the leakage source (see Figure 4) and its consequences. The reactor cooling water at Wolf Creek is borated. Boric acid is dissolved in the water to help control the nuclear chain reaction in the core as uranium fuel is consumed. Once water leaked from the vessel evaporated, boric acid crystals remained behind, looking somewhat like frost accumulation.

Fig. 4 (Source: Freedom of Information Act response to Greenpeace)

The spray from leaking Penetration 77 blanketed many neighbors with boric acid as shown in Figure 5. The vertical tubes are made from metal that resists corrosion by boric acid. The reactor vessel (the grayish dome-shaped object on the left side of the picture) is made from metal that is considerably less resistant to boric acid corrosion. The inner surface of the reactor vessel is coated with a thin layer of stainless steel for protection against boric acid. The outer surface is only protected when borated water doesn’t leak onto it.

Fig. 5 (Source: Freedom of Information Act response to Greenpeace)

The white-as-frost blankets coating the penetrations indicated little to no corrosion damage. But rust-colored residue in the Figure 6 pictures is a clear sign of corrosion degradation to the reactor vessel head by the boric acid. It may not be déjà vu all over again, but it’s too much Davis-Besse all over again. Boric acid corroded the Davis-Besse reactor head all the way down to the thin stainless steel liner. The NRC determined Davis-Besse to have come closer to an accident than any other US reactor since the March 1979 meltdown at Three Mile Island.

Fig. 6 (Source: Freedom of Information Act response to Greenpeace)

Fortunately, the degradation appears much worse in the pictures than it actually was. Actually, fortune had an ally at Wolf Creek that was missing at Davis-Besse. Both reactors exhibited signs that reactor cooling water was leaking into containment. The indicated leak rates at both reactors were below regulatory limits, except for one anomalous indication at Wolf Creek. Managers at Davis-Besse opted to dismiss the warning signs and keep the reactor operating. Managers at Wolf Creek heeded the danger signs and shut down the reactor. It’s not that they erred on the side of caution—putting nuclear safety first must never be considered an error. It’s that they avoided making the Davis-Besse mistake of putting production ahead of safety.

Wolf Creek restarted on November 21, 2016, after repairing Penetration 77, removing the boric acid, and verifying no significant damage to other penetrations and the reactor vessel head. But they also conducted refueling activities—already planned to require 55 days—during that 80-day period. The NRC closely monitored the response to the leakage and its repair and found no violations.

Davis-Besse chose production over safety but got neither. The reactor was shut down for over two years, generating no revenue but lots of costly repair bills. The reactor vessel head and other components inside the containment extensively damaged by boric acid corrosion were replaced. Many senior managers at the plant and in the corporate officers were also replaced. And the NRC fined the owner a record $5,450.000 fine for numerous safety violations.

Nuclear Safety Snapshot

Figure 7 shows the reactor vessel head at Wolf Creek without any boric acid blankets and corrosion. But the image I’ll remember about this event is neither this picture, nor the picture of the hole in Penetration 77, nor the picture of the boric acid blankets on adjacent penetrations, and nor the picture of rust-colored residue. It’s the mental picture of operators and managers at Wolf Creek who, when faced with Davis-Besse-like cooling water leak indications, responded unlike their counterparts by shutting the reactor down and fixing the problem rather than rationalizing it away. It’s an easy decision when viewed in hindsight but a tough one at the time it was made.

Davis-Besse made headlines, lots and lots of headlines, for exercising very poor judgment. Wolf Creek may not warrant headlines for using good judgment, but they at least deserve to be on the front page somewhere below the banner headline and feature article about today’s bad guys.

Fig. 7 (Source: Freedom of Information Act —response to Greenpeace)

Nuclear Safety Video

Unfortunately, the picture of Wolf Creek responding well to a safety challenge is a snapshot in time that does not assure success in facing tomorrow’s challenges.

Fortunately, the picture of Davis-Besse responding poorly to a safety challenge is also a snapshot in time that does not assure failure in facing future challenges.

Nuclear safety is dynamic, more like a video than a snapshot. That video is more likely to have a happy ending when the lessons of what worked well along with lessons from what didn’t work factor into decision-making. Being pulled away from bad choices is helpful. Being pushed towards good choices is helpful, too. Nuclear safety works best when both forces are applied.

The NRC and the nuclear industry made quite the hullabaloo about Davis-Besse. Why have they been so silent about Wolf Creek? It’s a swell snapshot that could help the video turn out swell, too.