Fission Stories #179

Earlier this summer, the owner of the Turkey Point nuclear plant in Florida requested and the NRC approved a change in the maximum limit on cooling water used by plant. For years, the plant had operated with the limit at 100°F. The plant could only continue operating for a few hours when this limit was exceeded. But power uprates and global warming conspired to cause problems with this limit.

Turkey Point uses an extensive canal network for its cooling water needs. Pumps pulled water from the canals and routed it through the plant to remove waste heat. The warmed water was discharged back into the canals. Long peninsulars of dirt forced the warmed water to wind back and forth literally for miles before it could again be drawn into the plant. En route, the warmed water would surrender some of its thermal energy to the air so as to be a little cooler for its next trip through the plant.

On September 26, 1996, the NRC approved a 4.5% increase in the maximum power level of the Unit 3 and 4 reactors at Turkey Point. On June 15, 2012, the NRC approved a 15% increase in each reactor’s maximum power level. Nuclear power reactors like those at Turkey Point are only about 33% efficient—for every three units of energy produced by the reactor core, only one unit goes out on the transmission lines as electricity while two units must be discharged as waste heat or thermal pollution. The higher power levels that NRC allowed Turkey Point’s reactors to operate, the more waste heat had to be released into the canal network.

Global warming only compounded that situation by warming both the temperature of the water in the canals and the temperature of the air cooling the canal water.

As the NRC reviewed the plant owner’s request to increase the cooling water temperature limit from 100°F to 104°F, I received several inquiries regarding safety implications of the proposed increase. My review of the paperwork the owner submitted to the NRC justifying the requested increase showed how it would have little to no impact on safety margins.

Turkey Point takes water from the canals for two purposes: (1) to cool the steam used to spin the turbine-generator to make electricity, and (2) to cool emergency equipment during an accident. For both purposes, the canal water flows through exchangers to cool steam or hot water that gets re-used by the plant. The canal water, warmed by several degrees, is returned to the canal network.

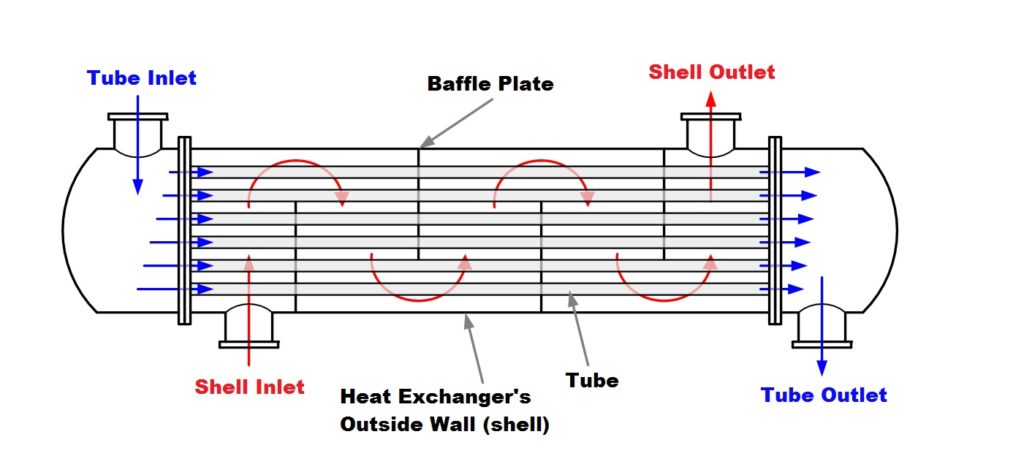

Shell and tube heat exchangers are commonly used to transfer waste heat to cooling water from the nearby lake, river, ocean, or canal system.

In Figure 1, blue represents the water from an internal plant cooling system. For example, the component cooling water (CCW) system for each reactor at Turkey Point was three pumps and two heat exchangers. Only one pump and heat exchanger is needed to handle the heat loads during an accident—the others are provided for increased reliability. The CCW system cools safety equipment like the emergency diesel generators and the areas housing the emergency core cooling system pumps. The CCW system water enters to the lower right of the heat exchanger, flows leftward through its tubes, and leaves via an outlet to the upper left.

Canal water is represented in red on the schematic in Figure 1. It enters the shell of the heat exchanger to the upper left and passes rightward past the tubes before leaving via an outlet to the lower right. Baffles force the canal water to weave its way back and forth across the tubes, maximizing the amount of time this water stays in contact with the tubes.

Heat conducts through the thin metal tube walls resulting in the canal water leaving the heat exchanger a few degrees warmer while the CCW system water is a few degrees cooler.

In the original design, canal water entering the plant, and this CCW heat exchanger, at 100°F was able to cool the CCW system water enough to adequately handle all the heat loads under accident conditions.

Increasing the canal water’s maximum temperature limit to 104°F did not alter this safety outcome for this simple reason—the heat exchangers had available margin. The heat exchangers have many more than the seven tubes illustrated in this simplified drawing. Workers plug tubes when the thin metal walls break. And debris inside the canal water sometimes clogs other tubes. The heat exchangers have available margin built into them so that an entire heat exchanger need not be replaced every time a single tube gets plugged or clogged.

The available margin also enables the heat exchanger tubes to experience some degradation and still remain functional. Scaling, rusting, biological growth, and other mechanisms can foul the tube walls. The performance of essential heat exchangers must be tested periodically to measure performance and verify safety margins are maintained. If not, the tubes must be cleaned or other actions taken to restore the necessary margins.

The 4°F canal water temperature increase does not prevent the heat exchangers from removing the required thermal energy from the CCW and other vital plant cooling systems. The increase may mean that workers can plug fewer tubes and/or that the tubes require cleaning more frequently. But it doesn’t mean that the plant’s safety margins have been compromised and is the reason that the NRC approved the increase.

Our Takeaway

Turkey Point’s owner also requested and received enforcement discretion from the NRC, allowing the plant to continue operating with canal water temperature exceeding 100°F while the requested increase was being reviewed. The owner also asked the NRC to review the requested increase on an expedited basis, short-cutting the normal process and its opportunities for public notice and comment.

Really?

Did global warming catch them by surprise? It’s been in the papers and on the radio and television. There may have even been a Simpsons episode or two about it.

Or did the fact that global warming causes the temperature of earth, water, and air (i.e, the globe) to increase surprise them?

These are Rhettorical questions because their answers don’t mean a damn. The first two, three, and perhaps even four plant owners can claim to be surprised. But after the NRC approved cooling water temperature limit increases for Millstone Unit 2, Peach Bottom Units 2 and 3, and Millstone Unit 3 in just the past two years, the “didn’t know any better” excuse is quite lame.

And the NRC should not allow plant owners to use lame excuses to get express lane service. Turkey Point’s owner could have—and should have—submitted its request via the normal channels instead of making the NRC drop everything to review it ASAP and denying the public its full rights to review and comment on proposed changes.

Next time an owner comes to the NRC with such a lame excuse, the NRC must channel Nancy Reagan and just say no.

“Fission Stories” is a weekly feature by Dave Lochbaum. For more information on nuclear power safety, see the nuclear safety section of UCS’s website and our interactive map, the Nuclear Power Information Tracker.