An earlier commentary described how workers installing a fire retardant wrap around electrical cables inside Switchgear Room 3A at the Turkey Point nuclear plant in Florida inadvertently triggered an explosion and fire that blew open the fire door between the room and adjacent Switchgear Room 3B.

I submitted a request under the Freedom of Information Act (FOIA) for all pictures and videos obtained by the special inspection team dispatched by the NRC to Turkey Point to investigate this event. The NRC provide me 70 color pictures in response to my request. This post updates the earlier commentary with some of those pictures.

The workers installing the fire retardant wrap cut the material in the hallway outside the switchgear rooms, but trimmed the material to fit as they put it in place. The trimming process created small carbon pieces. Ventilation fans blowing air within the switchgear room carried the carbon fiber debris around. The picture taken inside Switchgear Room 3A after the event show some of the carbon fiber debris on the floor along with debris caused by the fire and explosion (Fig. 1).

Fig. 1 (Source: Nuclear Regulatory Commission)

Some of the carbon fiber debris found its way inside metal panels containing energized electrical equipment. The debris created a pathway for electrical current to arc to nearby metal bolts. The bolts had been installed backwards, resulting in their ends being a little closer to energized electrical lines than intended. The electrical current was 4,160 volts, so it was quite a powerful spark as it arced to an undesired location (Fig. 2).

Fig. 2 (Source: Nuclear Regulatory Commission)

Law enforcement officers sometimes use Tasers to subdue a suspect. Taser guns fire two dart-like electrodes into the body to deliver an electric shock that momentarily incapacitates a person. The nuclear Taser at Turkey Point triggered an explosion and fire. The picture shows damage to a metal panel from the High Energy Arc Fault (HEAF) (Fig. 3).

Fig. 3 (Source: Nuclear Regulatory Commission)

Fortunately, there was not much combustible material within the switchgear room to sustain a fire for long. Fig. 4 shows some of the fire and smoke damage inside the switchgear room.

Fig 4 (Source: Nuclear Regulatory Commission)

The primary consequence from the explosion and fire in Switchgear Room 3A was damage to Fire Door 070-3 to adjacent Switchgear Room 3B. The Unit 3 reactor at Turkey Point has two switchgear rooms containing power supplies and controls for plant equipment. The fire door’s function is to prevent a fire in either room from affecting equipment in the adjacent room to minimize the loss of equipment (Fig. 5).

Fig. 5 (Source: Nuclear Regulatory Commission)

The metal fire door had a three-hour rating, meaning it was designed to remain intact even when exposed to the heat from a fire lasting up to three hours. The plant’s design assumed that a fire would be extinguished within that time. The plant’s design had also considered the forces caused by a HEAF event, but only looked at components within three feet of the arc. The fire door was more than 14 feet from the arc, but apparently was not aware of the 3-feet assumption (Fig. 6).

Fig. 6 (Source: Nuclear Regulatory Commission)

The force of the explosion pressed so hard against the fire door that it broke the latch and popped the door wide open. The fire door was more than 14 feet from the arc (even farther away after the explosion), but apparently was not aware of the 3-feet assumption (Fig. 7).

Fig 7 (Source: Nuclear Regulatory Commission)

I don’t have a picture of the fire door and its latch pre-explosion, but this closeup of the door’s latching mechanism suggests the magnitude of the force applied to popping it open. This picture also suggests the need to go back and revisit the 3-feet rule (Fig. 8).

Fig. 8 (Source: Nuclear Regulatory Commission)

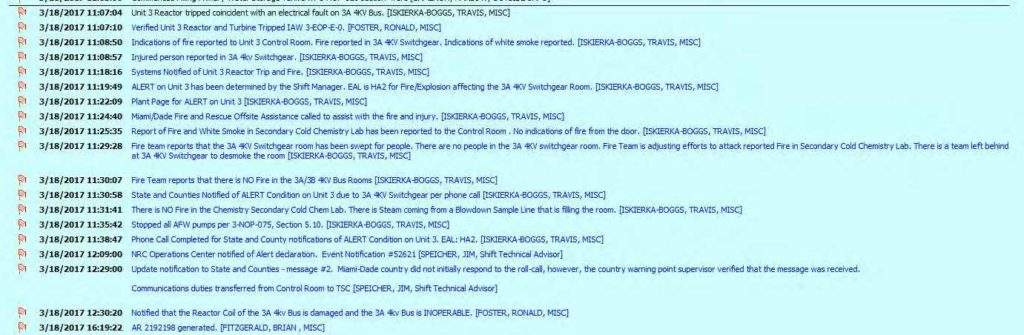

The explosion and fire triggered the automatic shutdown of the Unit 3 reactor. The Shift Manager declared an Alert, the least serious of the NRC’s four emergency classifications, due to the explosion and fire affecting equipment within Switchgear Room 3A. Workers called the local fire department for assistance with the fire and a worker injured by the explosion. This picture of the operations log noted some of the major events during the first 90 minutes of the event (Fig. 9).

Fig. 9 (Source: Nuclear Regulatory Commission)

UCS Perspective

The earlier commentary explained that two minor events occurred the month before the explosion and fire. In each of those events, carbon fiber debris from workers trimming material inside the switchgear room landed on electrical breakers and caused them to open unexpectedly and unwanted. But those warnings were ignored and the practice continued until a more serious event occurred.

This HEAF event is also a warning. It failed a barrier installed to prevent an event in one switchgear room from affecting equipment in the adjacent room. It had been assumed that a HEAF event could only affect components within 3 feet, yet the damaged door was more than 14 feet away. If the assumption now shown to be patently false does not lead to re-evaluations and necessary upgrades, shame on the nuclear industry and the NRC for not heeding this very clear, unambiguous warning.