Fission Stories #200

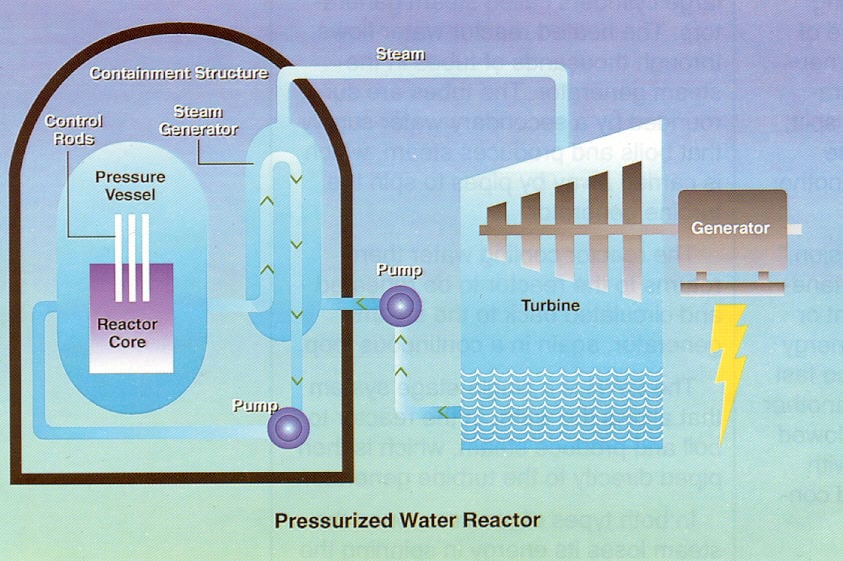

The Watts Bar Nuclear Plant near Spring City, Tennessee has two pressurized water reactors (PWRs) like that shown in Figure 1. Water flowing through the reactor core gets heated to over 500°F, but does not boil because pressure of over 2,000 pounds per square inch prevents it. The heated water flows through tubes inside the steam generators. Heat conducted through the thin metal walls of the tubes boils water surrounding the tubes. The steam flows through a turbine that spins a generator to make electricity.

Fig. 1(Source: Nuclear Regulatory Commission)

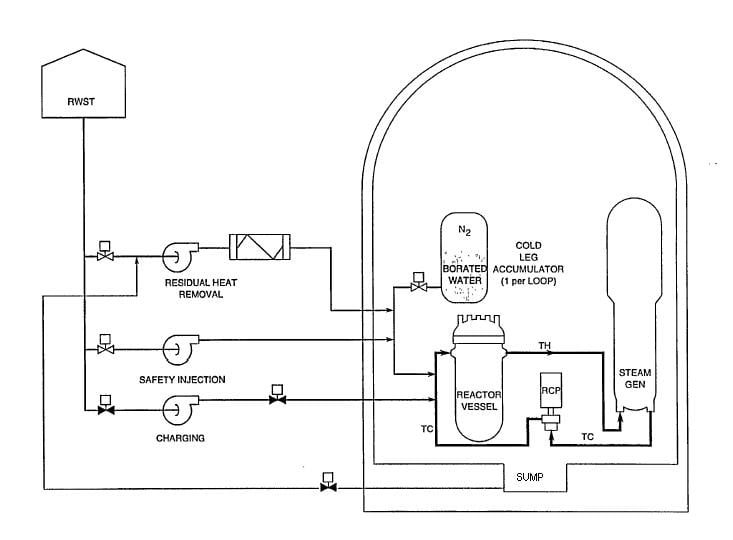

PWRs feature emergency core cooling systems (see Figure 2) intended to provide makeup water should a pipe connected to the reactor vessel break and rapidly drain the pressurized water from the vessel. Accumulators located inside the containment building are metal tanks partially filled with water. The remaining space inside the accumulator above the water level is filled with nitrogen gas. The nitrogen gas is pressurized. If a pipe breaks, the pressure inside the reactor vessel will decrease as water jets out the broken pipe ends. When the reactor vessel pressure drops below about 600 pounds per square inch, the accumulator water will be “pushed” into the reactor vessel. The charging, safety injection, and residual heat removal pumps located outside containment will start up and supplement the water makeup function.

Fig. 2 (Source: Nuclear Regulatory Commission)

The emergency core cooling (ECC) accumulators and pumps are designed to maintain adequate cooling of the reactor core for breaks of small, medium, or large diameter pipes connected to the reactor vessel. As shown in Figure 3, the size of the break determines how quickly the transition from the high head injection (e.g., charging pumps) systems to the low pressure systems.

Fig. 3 (Source: Nuclear Regulatory Commission)

Each PWR at Watts Bar has two charging pumps. Each charging pump is powered by an electric motor and is designed to provide 150 gallons per minute of makeup flow at the high pressure conditions. The charging pumps are located within the auxiliary building that is adjacent to the reactor containment building. Because it gets warm in Tennessee during the summer and the running motors on the charging pumps give off more heat, air conditioning units called room coolers are installed in the auxiliary building to protect the charging pumps from overheating damage. (The irony is duly noted—the components installed to protect the reactor core from overheating damage are vulnerable to overheating damage themselves.)

Each room cooler consists of a bladed fan that blows air across metal tubes filled with cooling water. The air gets cooled down as it flows past the tubes. The fan is spun by an electric motor. A belt wraps around the motor shaft and fan shaft so that when the former rotates, the latter rotates too.

Revisions and re-revisions

On November 3, 1995, the shaft for a fan on one of the charging pump room coolers for Watts Bar Unit 1 was discovered to be damaged. Workers determined that the fan belt had been tightened too much, causing the fan shaft’s damage. The maintenance procedure for the room coolers was revised to include more guidance for properly installing and tensioning the fan belt. The procedure revision was a CAPR—corrective action to prevent recurrence.

And it did prevent recurrence, at least until 2011. A revision to the maintenance procedure in 2011 removed the guidance on proper tensioning of the fan belt.

Charging pump room cooler 1B-B was found broken on December 4, 2015. Workers disassembled the unit, repaired or replaced its broken parts, and reassembled it.

Charging pump room cooler 1B-B was found broken on August 3, 2016. Workers determined that the fan belt had been tightened too much which put more strain on the fan bearing causing it to degrade.

The corrective action was to re-revise the maintenance procedure to reinsert the guidance about properly installing and tensioning the fan belt. Workers also checked all other coolers at Watts Bar that had their fan belts tensioned during the 2011 revision to the maintenance procedure to ensure they were properly tightened.

Report to the Commission

The charging pumps provide high pressure makeup to the reactor vessel should a broken pipe cause a loss of coolant accident. If the pipe has a large diameter, the reactor vessel pressure will quickly drop down to the range where the accumulators and the residual heat removal pumps can supply the necessary makeup water. Following breaks of smaller diameter pipes, the reactor pressure will also decrease, albeit at a slower rate. An evaluation by Westinghouse, the vendor for the PWRs at Watts Bar, concluded that the charging pumps might be needed for up to 7.5 days during an accident.

An engineering evaluation by the owner concluded that a charging pump running without its associated room cooler would fail in about 74 hours due to overheating of its electric motor. Because the faulty room cooler could have prevented the charging pump from operating for the entire duration of its safety mission, the owner reported the problem to the NRC.

Our Takeaway

Workers at Watts Bar danced the nuclear hokey pokey. They started with the fan belt guidance out of the procedure, then took the step of putting the guidance into the procedure, back-stepped to remove the guidance, and re-took the step of placing the guidance back into the procedure. When it was in the procedure, the fan belt guidance seemed to protect against room cooler failures. Perhaps it’s time to stop the hokey pokey now that the useful guidance is once again in the procedure.

Right now, the nuclear industry seeks to significantly reduce costs through its Delivering the Nuclear Promise initiative while the Nuclear Regulatory Commission seeks to downsize through its Project AIM efforts. The lesson of this Watts Bar episode should not be lost upon the promisers and projectors. The workers who removed the fan belt tensioning guidance in 2011 were likely unaware of the reason it had been added back in 1995. Before the promisers and projectors discontinue this practice or eliminate that activity, they need to make really sure they are not undoing past fixes. Perhaps it is no longer necessary to do that thing, or perhaps it can be done more efficiently. But the reasons why practices were started need to be fully understood before they can be safely discontinued or streamlined.

In other words, put on the thinking caps and take off those hokey pokey dancing shoes.

“Fission Stories” is a column by Dave Lochbaum. For more information on nuclear power safety, see the nuclear safety section of UCS’s website and our interactive map, the Nuclear Power Information Tracker.

Featured photo: Tennessee Valley Authority